Jack Michaud

2025

Snowboard materials and shapes have come a long way since the 2000s. If your board is missing some of these features, it’s probably time for an upgrade!

Metal Laminates

Metal has been used in racing and high performance skis for decades. It creates a torsionally stiffer board, which is good for edge hold. When combined with rubber, the composite is more damp and better at absorbing vibration and chatter. This also improves edge hold and makes for a more comfortable ride.

Metal construction caught on with snowboard racers in about 2004. The most common metal used in ski and snowboard construction is Titanal, a brand name of an aluminum alloy made by AMAG in Austria. No, it doesn’t contain any Titanium other than trace amounts. A new aluminum-scandium alloy has recently hit the market, branded Scalium, by Ferreol Technologies in Canada. This is welcome as Titanal can be difficult to obtain.

Two thin sheets of metal are laminated into the board in traditional sandwich style, with one sheet somewhere below the core and one somewhere above. Two sheets are needed like this so that the thermal contraction of the metal in cold weather doesn’t affect the camber of the board. The metal’s job in the board is, like fiberglass, to provide strength. Fiberglass is strongest in tension along the direction of its fibers, which is why different weaves of fiberglass like biaxial and triaxial are used to accomplish different qualities of stiffness and feel.

Metal’s strength is isotropic – the same in every direction. This means a few things; a single layer of metal can take the place of multiple layers of fiberglass, and it is stronger in torsion when part of the composite. This creates a board that has better resistance to torsional deformation – the edge angle at the ends of the board is held closer to the edge angle under your feet. Metal has its own dampening characteristics as does fiberglass, but it is the perfect combination of metal and rubber that creates the elusive balance of dampness and liveliness. Bruce Varsava of Coiler Snowboards says “metal seems to provide a totally different dynamic flex whereas the boards will flex a bit more when pushed to get more varied arcs. Its quality to stick well on ice is better than glass in any head to head test I have done. Its just magic!”

Complex Sidecuts

The curve in the side of the board used to be just a simple section of one large circle with a known radius. Sidecut of course is what allows the board to bend into an arc that carries us around the turn. A board with no sidecut would just travel in a straight line if you tried to carve it and did not forcefully steer it. Other shapes have been used over the years, like quadratic (parabola), elliptical, or VSR – variable sidecut radius. VSR was usually just two or three circular curves with different radii butted together end to end. Kessler Snowboards introduced a novel sidecut design using clothoid curves. These are basically fancy spirals that are also used in roller coaster loops. They combined this with the use of clothoid curves in the shape of the decambered nose and tail regions of the board to come up with an overall board shape that is in harmony with itself in 3 dimensions. They call this KST – Kessler Shape Technology.

Other snowboard makers have followed suit with their own advanced mathematics, or clothoid curves as well. Even though these are continuously changing curves, for the sake of conversation we can continue to think of these curves as approximately VSR, with two or three sections of different radius. Kessler sidecuts generally follow a pattern of a shorter radius in the front of the board, a longer radius in the middle of the board, and a medium radius in the tail of the board. For their GS boards, the tail section does not shorten as much as the SL boards do.

There are a few benefits to this. At low edge angles like when cruising, the long radius middle section is doing most of the work. The decambered nose and tail are not pressured into the turn as much. As you tilt the board up higher, the shorter radii in the nose and tail become more engaged and they work together to bend the middle of the board more. This creates a board that runs smooth when you want to go long, but that can turn tighter than when you crank it up. Very versatile.

The different regions of the sidecut also come into play more in different phases of the turn. At the top of the turn where speed, edge angle, and edge pressure are lowest, we are typically weighting our front foot more, engaging the nose of the board. The shorter radius in the nose is a better match for the forces in play. It pulls the rest of the board into the turn. In the middle of the turn, edge angle is higher and the nose and tail are fully engaged, helping to bend the longer middle of the board. Towards the bottom of the turn we typically have our weight shifted back on the rear foot, so the tail of the board is more engaged. The medium radius here helps to finish the turn, but it makes sense that it is not as tight as the sidecut in the nose, because speed, edge angle, and edge pressure are highest. Some GS boards have a sidecut that is strictly increasing in radius from nose to tail for maximum speed and acceleration out of the turn finish.

Other snowboard manufacturers have used opposite theories for VSR sidecut design, which Coiler called “Contra”, with sections that are shorter radius in the middle of the board and longer radius at the ends. This creates a very different feel that some people love and some people do not. Their main selling point is that they can create a lot of edge grip with less effort.

TLDR: variable sidecut radius creates a versatile board that works better for a wider range of carve sizes, and can be manipulated more by moving your weight fore and aft.

Decambered Nose

This feature allows the nose of the board to initiate predictably, slice cleanly through the snow rather than plow through it, and to absorb bumps and ruts more gracefully.

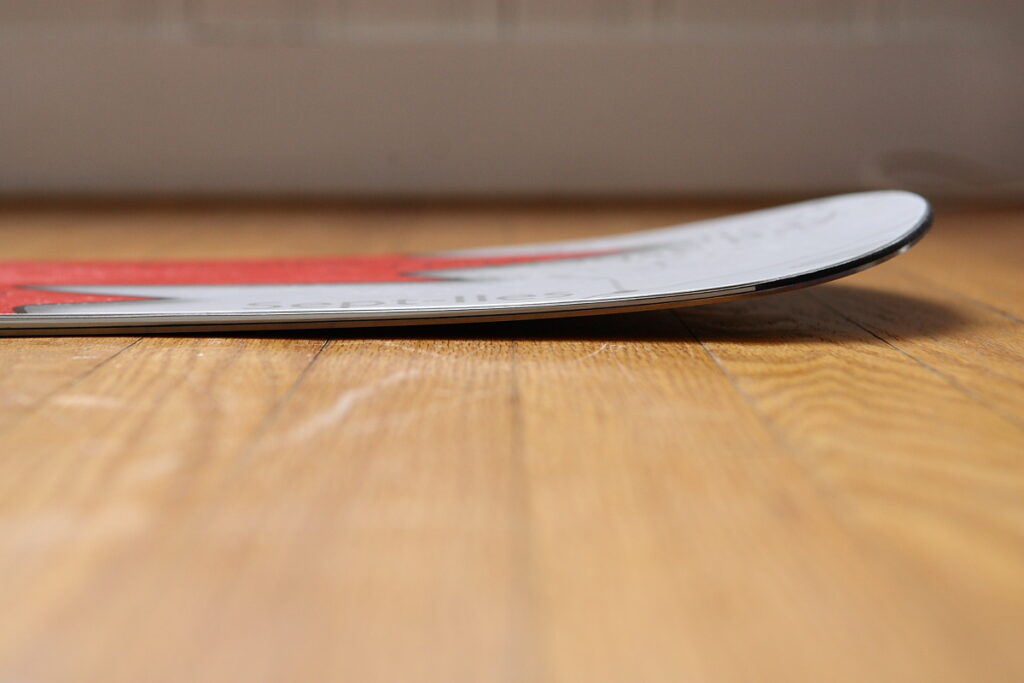

These pictures illustrate the differences between a traditional nose and a decambered nose.

The decambered nose effectively becomes part of the sidecut when the board is tilted on edge. It works with the sidecut instead of against it. The upward curve of the nose aligns better with the curve of the sidecut and the shape the board becomes when the whole thing is bent into a carve.

As you can see in the picture below, when a board is carving, the nose is engaged in the snow well past the end of the so-called “running length” of the board:

Therefore the upturn of the nose becomes an active part of the sidecut and an active participant in the carve. A traditional nose shape that curves up abruptly will “plow” through the snow because it is trying to turn along the upward curve of the nose – a much tighter arc than the rest of the board. A low, decambered nose will “slice” through the snow better because its curve is more inline with the sidecut. The decambered nose does not result in a huge reduction in effective edge length, because the board is still engaged in the snow along most of its length as we can see here:

The nose is now “unloaded” and not fighting the sidecut or the forward movement of the board. The decambered nose also helps with bumps and imperfections in the snow surface because the contact point is not as pressured into the snow as a traditional nose. With a traditional nose, any impact to the nose of the board as it is carving will be more abrupt, because the nose upturn is more vertical and curves up at a tighter radius. The nose has to climb up over the obstacle more quickly, in a shorter length of board travel. This creates a shockwave that travels down the board, compromising edge hold and possibly upsetting the rider. The decambered nose spreads the impact out more gradually, and the whole front of the board has more time to deflect more gently.

Exotic materials

Fabrics other than fiberglass are common in higher end boards, and can even replace metal now. Quasi-isotropic carbon fiber has woven fibers running in multiple balanced directions. For example, a layer running at 0º orientation, another at 60º, and another at 120º. This creates a laminate with constant strength no matter which way you position it. Q-iso carbon fiber is often used to replace metal in an application where metal’s isotropic strength is desired but other properties of metal are not appropriate, like conductivity or thermal reaction.

Zylon is another exotic fiber in the Aramid family, which includes Kevlar. It is being campaigned with success in World Cup and the Olympics by Virus snowboards, in boards made without metal.